Evolve creates successful innovative products with less

time, less risk and less cost while improving our clients’

bottom line.

About Us

Evolve offers product design and development services from concept to production.

Evolve is a product design consulting firm with manufacturing and plastics expertise, specializing in world-class product development services and committed to creating successful innovative products and to helping industry leaders enhance their position in the global market.

Why Choose Evolve

Services

Our 4D Process

1. Discover

Research new opportunities

2. Define

Explore and define new ideas

3. Design

Prove out and validate concepts and ideas

4. Deliver

Ensure successful product launch

Portfolio

Mobile Rechargeable Battery

Violin Shoulder Rest

Battery and Energy Storage

Micro Hearing Instrument

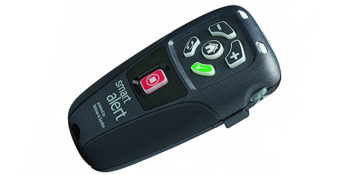

Alerting Remote Control

Computer Shopping Cart Handle

Office Seating Line

Premium Hard Case Packaging

Remote Control

Spring-Loaded Clip

Protective Footwear

Testimonials

“Aldo was instrumental in helping us achieve a vision for the industrial design for the Tech 2, an electronic automotive diagnostics tool.”

Enrique Alfaro, Former Senior Experimental Engineer, General Motors, Service Techonology Group

“ Over the years, Aldo has been a great asset to our design and engineering development team on many projects. ”

Marc Fortin, Product Planning Manager, Electrolux Major Appliances

“ When you have people like that on your project team, it is like building a cross functional team of molding, tooling, materials and design experts in one package. ”

Richard Peters, Secondary Operations Leader, Advanced Materials, SABIC Innovative Plastics (formerly GE Plastics)

“ Evolve Design Solutions has exceeded our expectations and went above and beyond what was expected of them. ”

Mat M.Seguin, President, iGoggles Eyewear

“ Evolve Design Solutions took our designs to a new level and helped make our product design world class. ”

Jim Phillips, President, Copernicus Educational Products

Evolve Design Solutions is a professional member of

SPE, SME, IDSA and supports the Designers Accord.

![]()